MS Bond All Adhesive

Category:

Adhesive

Application:

Features:

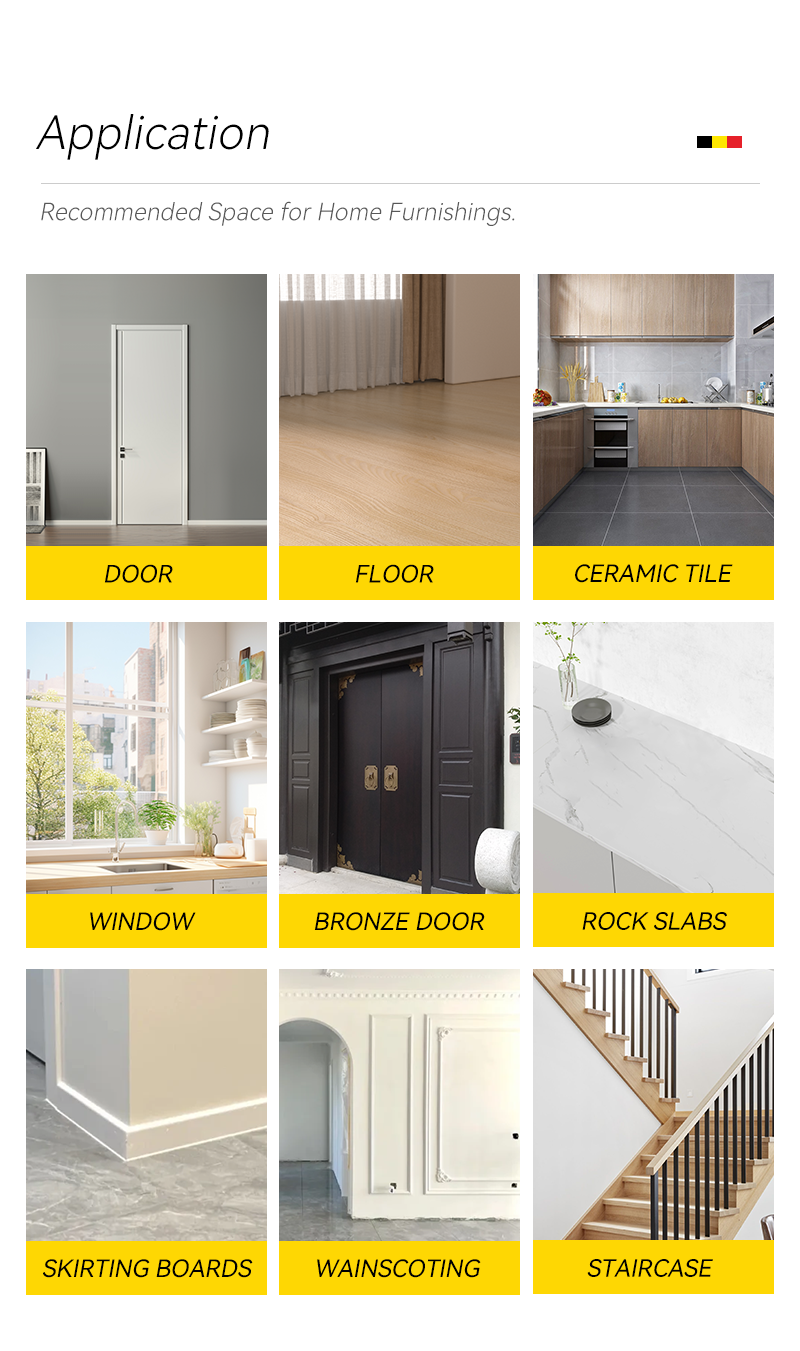

Suitable for bonding of basically all material surface, aluminium, aluminium & wood composites, ABS, steel, Zincalume, fiberglass, brick, colorbond, PVC flashing, concrete, ceramics, timber, MDF, plasterboard, polystyrene, glass, mirrors, tile, porcelain, etc. Also suitable for installation of different kind of materials big panels.

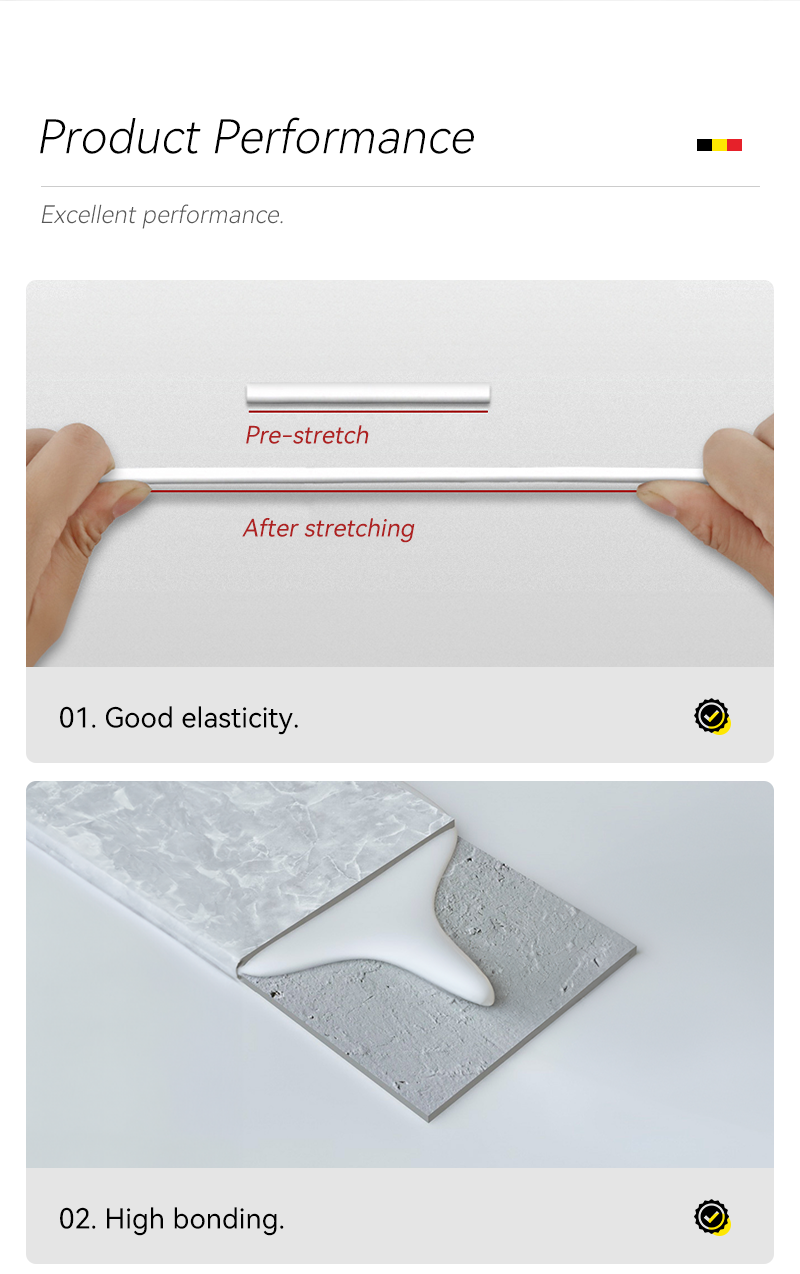

1. Grabs fast; 2. High impact resistance; 3. For almost all substrates; 4. Strong bonding performance

Product Profile:

天美传媒 Bond-All adhesive is mainly made of silane-modified polyurethane polymer, which also call MS polymer or MS sealant. This adhesive grabs almost all substrates fast with excellent bonding strength and high impact resistance.

Application:

Suitable for bonding of basically all material surface, aluminium, aluminium & wood composites, ABS, steel, Zincalume, fiberglass, brick, colorbond, PVC flashing, concrete, ceramics, timber, MDF, plasterboard, polystyrene, glass, mirrors, tile, porcelain, etc. Also suitable for installation of different kind of materials big panels.

Features:

1. Grabs fast; 2. High impact resistance; 3. For almost all substrates; 4. Strong bonding performance

MS Bond All Adhesive

| Parameter | |||

| Test items | Unit | Testing Standard | Test results |

| Apperance | —— | Product should be a fine, uniform paste without air bubbles, crusts or gels | meet the requirements |

| consistency | cm | specified value 7.5 ± 1 | 7.5 |

| density | g/cm3 | specified value±0.1 | 1.64 |

| Surface curing time | min | ≤60 | 20 |

| Sag | mm | ≤3 | 0.5 |

| extrusion | ml/min | ≥150 | 400 |

| Hardness | HA | 30 - 90 | 50 |

| Anti-yellowing | 168H/△E | ≤ 6 | < 2 |

| Bonding Strength | MPa | ≥ 2 | 3 |

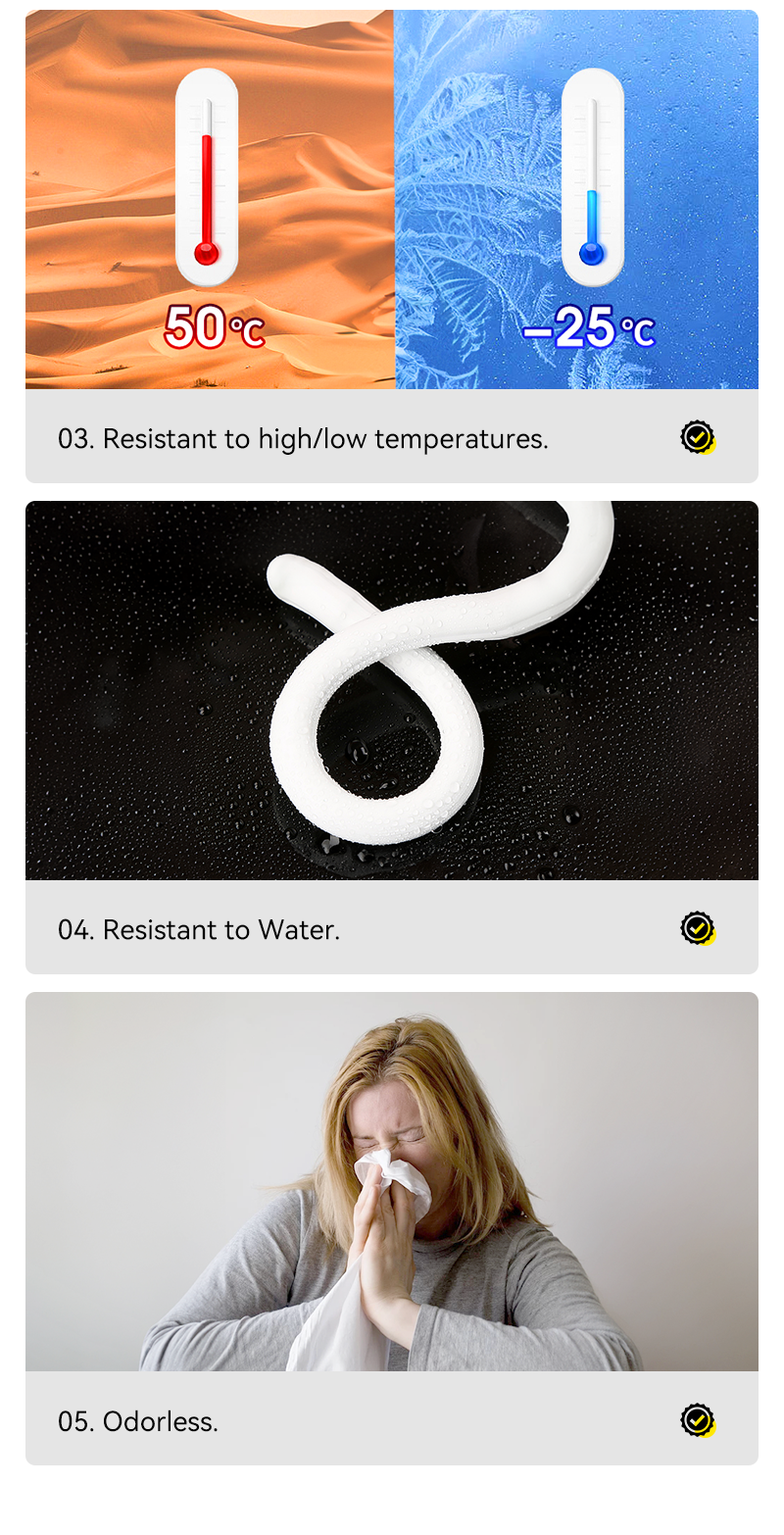

| Tensile modulus | MPa | HM: 23℃: >0.4 or -20℃:>0.6 | 23℃: 1.0; -20℃: 1.2 |

| Tensile adhesion | —— | no damage | no damage |

| Tensile adhesion after flooding | —— | Soak in 23℃ water for 4 days, put it under standard test conditions for 1 day and then test: no damage | no damage |

| Cohesion after cold drawing - hot pressing | —— | (Store at -20℃ for 3h, stretch for 21h: place at 70℃ for 3h, compress for 21h: after repeating one round, place for 3d under standard test conditions) is a cycle, after 2 cycles: no damage | no damage |

| mass loss rate | % | ≤8 | 1.3 |

| For more information, please send inquiry. | |||

Prev

Epoxy Adhesive

Next

More Products

Leave A Message